How it Works

The FogClean® system disinfects surfaces while also effectively neutralizing airborne pathogens.

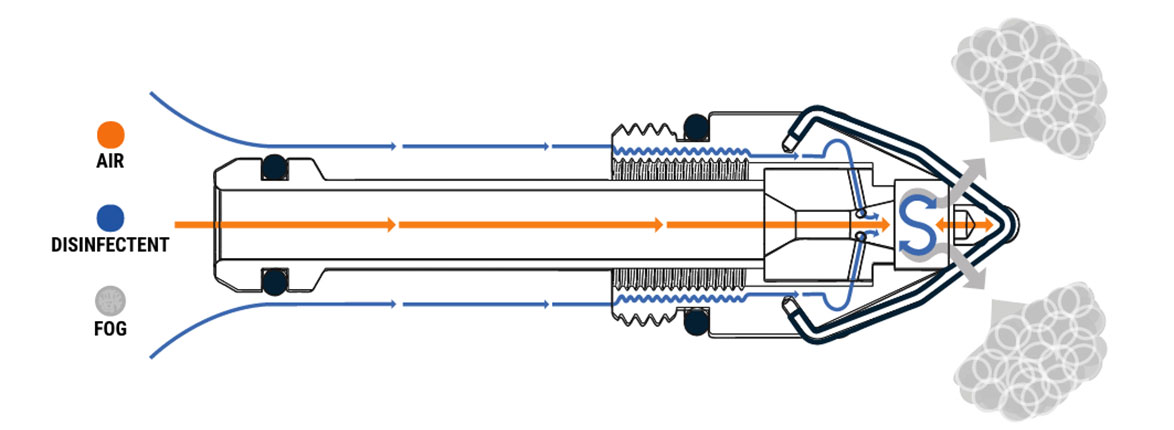

The design of the FogClean® system is based on a unique nozzle that atomizes liquid and produces a very dense fog of 0-10 micron size droplets. These droplets create a fog that blankets the area allowing for quick and effective dispersion of disinfectant. A typical 150 square foot room (13 square meters) can be filled in less than 50 seconds, using approximately 0.07 gallons (0.26 liters) of solution. A typical 10,000 square foot facility can be completely sanitized in less than one hour, using only 1-2 gallons (7.5 liters) of solution.

FogClean products can use any liquid or water soluble disinfectants. To check the characteristics of various types of disinfectants effective on Covid-19, the EPA has a list of approved disinfectants at https://www.epa.gov/pesticide-registration/list-n-disinfectants-use-against-sars-cov-2-covid-19. There are several plant based disinfectants that are also approved by the FDA and are safe for humans. These can typically be applied without using PPE and are safe for use around food. One such disinfectant can be found at https://giccllc.com/path-away.html

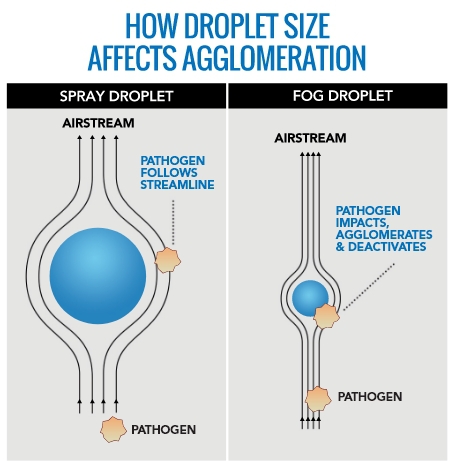

Dry Fog is described as droplets below 10um in size creating a fog that floats in the air without leaving appreciable moisture in the area. It will build the humidity inside the area, but not leave any residue on items inside the area being disinfected. Wet Fog will have droplets above 20um in size, leaving a residue on areas of interest. This could be used if the person disinfecting wants to leave a residue on touch surfaces or ensure more solution on touch surfaces versus areas of moisture sensitivity. Some disinfectants also call for wetting a surface with solution for a period of time to be effective. Be sure to review the product label of your disinfectant.